CUSTOMER ALERT Beware of fraudulent websites using our name. We do not sell on Craigslist or Facebook Marketplace. Report suspicious contacts to 713-670-8801.

10 Essential Tips for Using Refrigerated Shipping Containers Effectively?

Refrigerated shipping containers play a crucial role in the transportation of perishable goods. These insulated units maintain a stable temperature, ensuring that items like food and pharmaceuticals arrive fresh and safe. However, many businesses struggle with maximizing their effectiveness.

Understanding how to use a refrigerated shipping container efficiently is vital. For instance, overloading a container can lead to temperature fluctuations. Proper spacing within the container allows air to circulate, preventing spoilage. Even small details matter, such as ensuring the doors seal tightly to maintain the ideal environment.

Mistakes can happen, leading to loss and waste. It's essential to regularly monitor temperatures during transit. Regular checks help identify issues before they escalate. Recognizing the importance of each step can significantly improve outcomes. With careful attention, refrigerated shipping containers can be an invaluable asset in shipping perishable goods effectively.

Understanding the Basics of Refrigerated Shipping Containers

Refrigerated shipping containers play a crucial role in transporting perishable goods. They maintain a consistent temperature, ensuring items like fruits, vegetables, and pharmaceuticals stay fresh. According to a 2021 industry report, the refrigerated shipping container market is expected to grow by 5.2% annually, reflecting rising demand for temperature-sensitive products.

Understanding how these containers function is essential for maximizing their benefits. Various models are available, catering to different load sizes and temperature requirements. For example, a standard container can maintain temperatures as low as -25°C, which is vital for transporting frozen goods. However, not all containers meet these specifications. Some may lack insulation, leading to potential spoilage.

It's critical to monitor the temperature regularly during transit. A study found that improper temperature management can result in a 30% loss of perishable inventory. Moreover, choosing the right container size matters. Oversized containers lead to higher energy costs. Under-sized ones may overheat. Therefore, proper selection and monitoring are key to effective use.

Choosing the Right Type of Refrigerated Container for Your Needs

Choosing the right type of refrigerated container is crucial for ensuring the quality of your goods during transport. There are various types available, each suited for different needs. For example, consider the temperature requirements of your products. Some may need freezing while others just require refrigeration. Understanding these needs is the first step.

When selecting a container, check the insulation quality. Poor insulation can lead to temperature fluctuations. It's essential to pick a container that maintains a consistent environment. Also, don’t forget about size. A container that is too big can waste energy, while one that is too small can compromise the product's integrity.

One important tip: always monitor temperature levels during transport. Sometimes, equipment failures can happen unexpectedly. Regular checks can help you catch issues early. Additionally, look for containers with built-in monitoring systems. They can alert you to any temperature changes in real time. These small steps ensure your cargo arrives in the best condition.

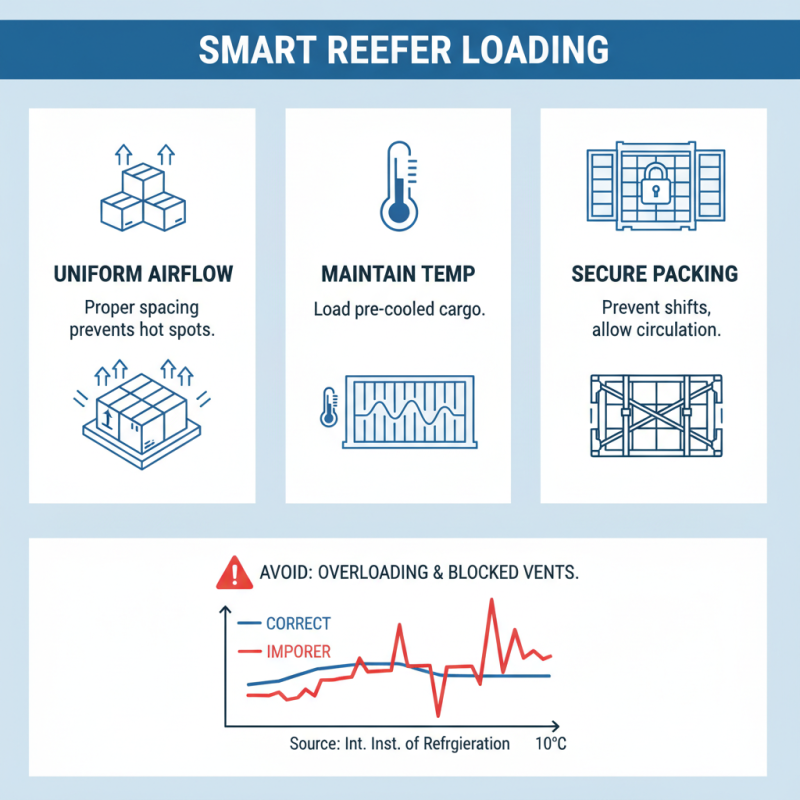

Proper Loading Techniques for Optimal Temperature Control

Proper loading techniques are crucial when using refrigerated shipping containers. Ensuring that cargo is packed correctly can prevent temperature fluctuations. According to a study by the International Institute of Refrigeration, improper loading can lead to temperature deviations of over 10 degrees Celsius. This can spoil sensitive products.

One effective tip is to avoid overloading the container. Overloading restricts airflow, causing uneven cooling. Arrange items in a way that air can circulate freely. Use dunnage or packing materials strategically. This will help stabilize the temperature within the container. Remember, maintaining a consistent temperature is vital.

Another tip is to pre-chill items before loading them into the container. Ideally, products should be at the desired temperature to begin with. The USDA suggests that food products should be cooled to below 4 degrees Celsius before shipment. This reduces the load on the refrigeration unit. Always monitor the cargo during transit. Small adjustments can save a shipment from spoilage. Consider using temperature sensors to keep track of conditions inside the container. They provide real-time data and help identify issues promptly.

Monitoring Temperature and Humidity During Transit

Monitoring temperature and humidity during transit is crucial when using refrigerated shipping containers. Inadequate control can lead to spoilage or damage to goods. Proper equipment is essential. Use temperature sensors and humidity gauges inside the container. Regular checks can help catch issues early.

It’s also important to record data continuously. This allows for tracking fluctuations. If problems arise, you can identify patterns. A sudden rise in temperature might signal a malfunction. Ensure all staff are trained to recognize these signs. Miscommunication can lead to disastrous results.

Don’t forget about human error. Even with the best equipment, mistakes occur. Regular audits of systems can help mitigate risks. Set reminders for routine checks, and don't skip them. Reflecting on past shipments can offer insights. Consider the lessons learned from any failures. Adapting your approach can enhance future transits.

Monitoring Temperature and Humidity During Refrigerated Shipping

Maintenance and Care Tips for Long-lasting Refrigerated Containers

Refrigerated shipping containers are essential for transporting temperature-sensitive goods. To maximize their lifespan, regular maintenance is crucial. Start by conducting routine inspections. Check the seals and insulation for any wear. Damaged seals can lead to temperature fluctuations, impacting the contents.

Cleaning is another key aspect. Use mild detergents and water to clean the interior walls regularly. Residue buildup can affect air circulation. Ensure drainage systems are clear. Clogs can cause water accumulation, leading to mold growth. Maintenance should be a proactive effort. Neglecting minor issues can lead to costly repairs later.

Temperature settings need regular checks. Often, users set these too low or too high, causing inefficiencies. Calibration of the unit should happen at regular intervals. Small adjustments can make a big difference. Keeping a log of maintenance actions helps track issues. This not only aids in repair but also enhances operational efficiency.

Related Posts

-

2026 Best Refrigerated Shipping Container Options Reviewed

-

Why 10x10 Shipping Containers Are the Ultimate Solution for Your Storage Needs

-

Top 10 Uses for a 40ft Shipping Container You Need to Know About

-

The 10 Best Uses for a 40ft Shipping Container You Need to Know

-

The Ultimate Guide to Choosing Large Shipping Containers for Your Needs in 2025

-

Top 10 Tips for Choosing the Right Large Shipping Container for Your Needs