CUSTOMER ALERT Beware of fraudulent websites using our name. We do not sell on Craigslist or Facebook Marketplace. Report suspicious contacts to 713-670-8801.

How to Choose the Right Refrigerated Container for Your Needs?

When it comes to choosing the right refrigerated container, the decision can be challenging. Industry expert John Smith once said, "Selecting the perfect refrigerated container is essential for preserving quality." With many options available, understanding your specific needs is crucial.

Refrigerated containers come in various sizes and configurations. They must maintain specific temperature ranges for optimal performance. For example, certain goods require strict temperature control, while others may be more forgiving. It’s important to consider what you are transporting. Some choices may not fit all products equally well.

Additionally, cost is a significant factor. Budget constraints can limit your options. However, investing in the right refrigerated container can save money in the long run. On the flip side, overspending may lead to regret if your needs change. Assessing both short-term and long-term goals is vital in this decision-making process.

Types of Refrigerated Containers Available in the Market

When selecting a refrigerated container, understanding the types available is crucial. There are mainly three categories: shipping containers, portable units, and bulk containers. Each serves a different purpose based on user needs. Shipping containers are typically used for long-distance transport. Portable units offer flexibility in various settings, while bulk containers are ideal for large quantities.

According to industry reports, the global refrigerated container market was valued at around $2 billion in 2020. It's projected to grow by 6% annually through 2025. This growth reflects an increased demand in sectors like food and pharmaceuticals. However, not all containers meet the same refrigeration standards. Some units may lack insulation efficiency, affecting temperature control during transportation.

Choosing the right type can be tricky. Not all containers maintain the same temperature range. The risk of spoilage due to an inadequate unit is real. Inadequate tracking systems can compound these issues, leading to potential losses. Understanding your specific needs is vital before making a decision.

Types of Refrigerated Containers Available in the Market

This bar chart illustrates the popularity of different types of refrigerated containers available in the market. The Reefer Container is the most popular choice, followed by Insulated Containers and others. Understanding these trends can help you choose the right refrigerated container for your needs.

Key Factors to Consider When Choosing a Refrigerated Container

When it comes to choosing a refrigerated container, several key factors should be at the forefront of your decision-making process. Understanding the temperature range is critical. Different goods require specific temperature settings. For instance, fresh produce often needs 32°F to 37°F, while frozen items need 0°F or below.

Another crucial aspect is the size of the container. Depending on your storage and shipping needs, the size can significantly impact efficiency. A report by the International Institute of Refrigeration shows that many businesses underestimate required capacity, leading to inefficiencies. Don’t rush into a choice; consider your space properly.

**Tips:** Always measure your goods before selecting a container. This ensures you are not left with excess space or crowding. Consider insulation as well. Quality insulation minimizes energy costs and maintains a stable temperature.

Finally, think about the ease of use. Look for features like adjustable shelving and easy access doors. These can make a big difference in daily operations. Many users find that lacking these features leads to frustration. Invest time in envisioning how you will use the container in practice.

Assessing Your Storage and Transportation Needs

When choosing a refrigerated container, assessing your storage and transportation needs is crucial. Understand what products you will store. Different goods require different temperatures. For instance, seafood needs a lower temperature than fruits. Distinguishing these requirements is essential for maintaining quality.

Tips: Measure the volume of goods before selecting a container size. Underestimating capacity can lead to spoilage. It’s common to choose a bigger container, but it might waste energy. Adjusting your calculations can save money and resources.

Consider the distance and duration of transportation. Some containers are better for short trips, while others excel in long hauls. Be realistic about your delivery timelines. Some refrigeration units might struggle to maintain cool temperatures over extended periods.

Tips: Monitor the weather conditions. High ambient temperatures can affect cooling efficiency. Placing a thermometer inside can help track the temperature, ensuring your goods stay safe. It’s often an overlooked aspect of transportation planning.

How to Choose the Right Refrigerated Container for Your Needs? - Assessing Your Storage and Transportation Needs

| Container Type | Temperature Range (°C) | Capacity (Cubic Meters) | Ideal Use | Recommended Duration (Days) |

|---|---|---|---|---|

| Standard Refrigerated Container | -20 to 20 | 28 | General Food Storage | Up to 30 |

| Insulated Container | 0 to 10 | 15 | Pharmaceuticals | Up to 5 |

| Blast Freezer Container | -40 to -20 | 20 | Quick Freezing | Up to 10 |

| Thermal Cover Container | 5 to 20 | 10 | Transporting Fresh Produce | Up to 7 |

| Reefer Truck | -20 to 20 | 33 | Long-Distance Transport | Up to 14 |

Understanding Temperature and Insulation Requirements

When selecting a refrigerated container, understanding temperature and insulation is crucial. Different products require specific temperature ranges. For instance, fruits may need around 34°F (1°C) to stay fresh. Meat, on the other hand, often does best at lower temperatures. Knowing these requirements helps ensure your products maintain their quality.

Insulation is another key factor that affects temperature control. Good insulation minimizes heat exchange. This helps maintain the desired temperature inside the container. Consider the container's construction materials. Some options may not provide adequate insulation. This could lead to energy loss and spoilage of perishable goods.

Ventilation plays a role too. Proper airflow prevents hot spots and uneven temperatures. Some containers may need an extra fan to circulate air better. Evaluate the overall design for effective insulation and temperature consistency. Take time to research and understand these aspects, as the wrong choice can cost more than just money.

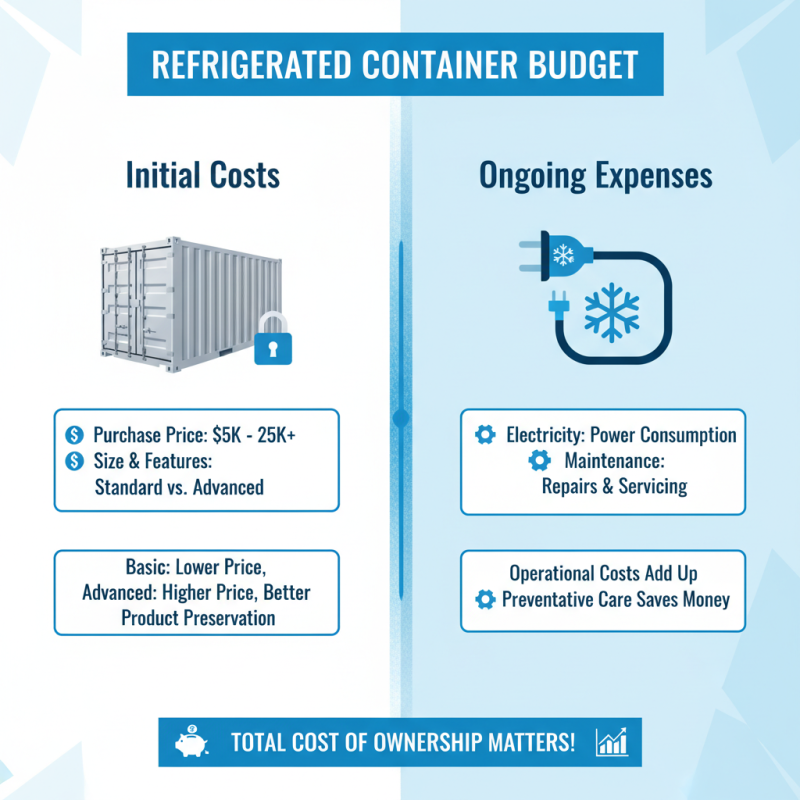

Budgeting and Cost Considerations for Refrigerated Containers

When budgeting for refrigerated containers, it's important to consider both initial costs and ongoing expenses. The upfront price can vary widely based on size and features. A standard container may be more affordable, but it might lack advanced temperature control. This could lead to quality loss in your products. Investing a bit more could ensure better preservation.

Ongoing costs include maintenance and energy consumption. Older units may consume more energy, resulting in higher bills. Regular maintenance is also essential to avoid costly repairs. You may think you’re saving, but a breakdown can lead to inventory loss. Sometimes, the cheapest option isn’t the best for long-term needs.

Think about your specific requirements. If you need to transport delicate items, a more advanced model might be necessary. This increases the initial expense but could save money in the long run. Consider not only the price tag but the total cost of ownership. This approach can help you make a more informed decision, ensuring you choose a container that fits your budget and meets your needs effectively.

Related Posts

-

2026 Best Refrigerated Shipping Container Options Reviewed

-

Top Benefits of Using a 40ft High Cube Container for Your Storage Needs?

-

10 Best Uses for a 20ft Shipping Container: Transform Your Space Today!

-

Top 10 Benefits of Using Refrigerated Containers for Your Business Needs

-

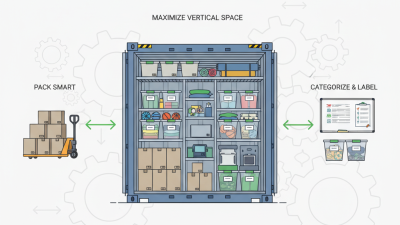

8 Tips for Maximizing Your 8x20 Storage Container Space?

-

20 Foot Storage Container Tips for Maximizing Space and Efficiency